Hanseatic nature and Hanseatic inspiration are under construction at Vard's shipyard in Tulcea, Romania, and will be completed at Vard in Norway for April and October 2019 deliveries.

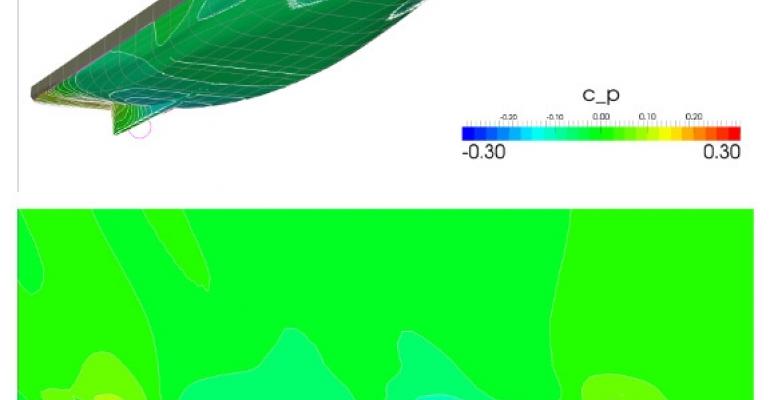

Brought in during the initial design and conception phase, DNV GL experts first created and explored more than 100,000 hull variations for the vessels. They worked to give Hapag-Lloyd Cruises and Vard an idea of the technical possibilities of various hull forms and how the interactions between the hull form, the initial general arrangement and stability requirements would impact fuel consumption.

'The design concept for the two new ships was "inspired by nature." The vessel interiors have been created to reflect the environments our passengers are experiencing inside the ships,' said Henning Brauer, head of newbuilds, Hapag-Lloyd Cruises. 'But these are also sensitive environments so reducing the environmental impacts of our vessels is an integral part of the design concept. Working with DNV GL has allowed us to significantly reduce fuel consumption, which also decreases our overall emissions.'

'We are very pleased to have been able to exceed Hapag-Lloyd Cruises’ expectations and offer an optimization solution that demonstrates that efficiency and sustainability can go hand in hand,' said Knut Ørbeck-Nilssen, CEO, DNV GL – Maritime. 'These results show that by bringing greater computing power and smart software to the ship design process we can help to unlock efficiencies for our customers.'

After the initial assessment, the efficiency of the hull form was optimized within the given constraint set using DNV GL’s formal optimization approach. During this phase, another 10,000 hull designs were analyzed, with the most promising candidates undergoing high fidelity computational fluid dynamic analysis to confirm the results. Finally, the stern was optimized for passenger comfort by minimizing impact from slamming.

'Because these ships will have the highest ice class possible for passenger vessels, PC6, fuel consumption is an essential factor in their economic feasibility,' added Juryk Henrichs, senior project engineer, DNV GL – Maritime. 'With roughly 7,000 CPUs doing the heavy lifting, our unique form-parametric hull model was able to identify the optimal design to meet Hapag-Lloyd Cruises’ specifications.'

Copyright © 2024. All rights reserved. Seatrade, a trading name of Informa Markets (UK) Limited. Add Seatrade Cruise News to your Google News feed.